The top racking solutions for warehouses in 2022

A storage option called racking allows goods to be piled horizontally on numerous levels. These solutions can help you manage your warehouse space more effectively, organize your freight to improve productivity, and manage inventory.

There are particular standards for each warehouse. The best racking system should be able to utilize space as efficiently as possible while causing the least amount of disruption to your operations, particularly during the picking procedure.

The top racking solutions for warehouses in 2022 are listed below.

Selective Racking System:

The selective racking system is the most often used because to its inexpensive cost and broad range of sizes and attachments. For any application that needs easy access to materials, this racking system is perfect for conventional storage.

Double-Deep Racking System:

A version that gives density a nice boost but requires specialized equipment (extendable forks) and takes more time to use is the double deep racking system. Selective racking combined with high-density racking offers the best of both worlds.

Pallet Flow/Live Racking System:

A high-density storage system called a pallet flow rack combines elevated rails with moving parts like gravity rollers and conveyors. These storage racks at the warehouse are propelled by gravity. This racking system is perfect for products with short shelf lives because it may double, triple, or even quadruple your warehouse's storage capacity.

Drive-In Racking System:

You may maximize the density of product storage in your warehouse by using the drive-in racking system. It reduces aisles in a warehouse and is perfect for packing a lot of similar goods into a small area.

Push Back Racking System:

By using separate lanes for each SKU, the push-back pallet racking system increases pallet storage while simultaneously enhancing selectivity, making it simpler to find, pick up, and store each SKU. Push back warehouse storage racks enable front loading and unloading, eliminating the need for multiple aisles.

Narrow Aisle Racking System:

In that, it makes it simpler to access each pallet; narrow aisle racking is similar to selective racking. High-density storage is produced by the warehouse storage racks by utilizing both floor area and roof height.

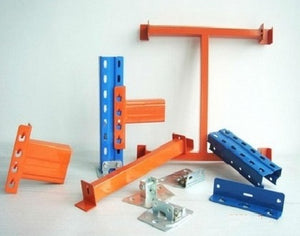

ISR Pallet Racking Collection

PALLET RACKING FRAMES

ISR Pallet Racking Frames are Certified and exceed Australian Standards. Our uprights are made to suit your specific business requriements.

PALLET RACKING ACCESSORIES

ISR offers all accessories to maximise your pallet racking productivity and capacity. Ranging for mesh decks to protectors, we have you covered.

PALLET RACKING BEAMS

ISR Pallet Racking beams are tested and certified to exceed Australian Standards. Our latest "Auto Safety Clip-on Pins" makes ours the safest on the market.

Why Would We Need a Racking System for a Warehouse?

For starters, installing a racking system is significantly less expensive than expanding an existing warehouse. The amount of goods you can handle in your warehouse can be doubled or even tripled by installing a racking system, and adding forklifts to a basic warehousing operation typically leads to a significant improvement in efficiency.

The bottom line is more important to businesses than ever before, and a warehouse without even the most basic racking system is almost always inefficient. Large commodity warehouses frequently include forklifts, which makes the transition to a racking system much simpler.

Choosing the best racking warehouse systems can be challenging due to the wide variety of racking systems that are offered on the market. The easiest way to avoid getting too involved in this pastime is to keep in mind the aspects mentioned above. Making the most of your available space and optimizing your warehouse procedures are both possible with the right warehouse racking system.